Aluminum Deep Drawing

Aluminum Deep Drawing - One of the biggest advantages of deep drawn aluminum hydroforming versus traditional. It influences the material formability ,the mechanical resistance of. Using a numerical representation, explanatory approaches for the observed phenomena are. Deep drawing friction is a key boundary condition for controlling the forming quality of aluminium alloy parts. Deep draw depth & process lesson four:

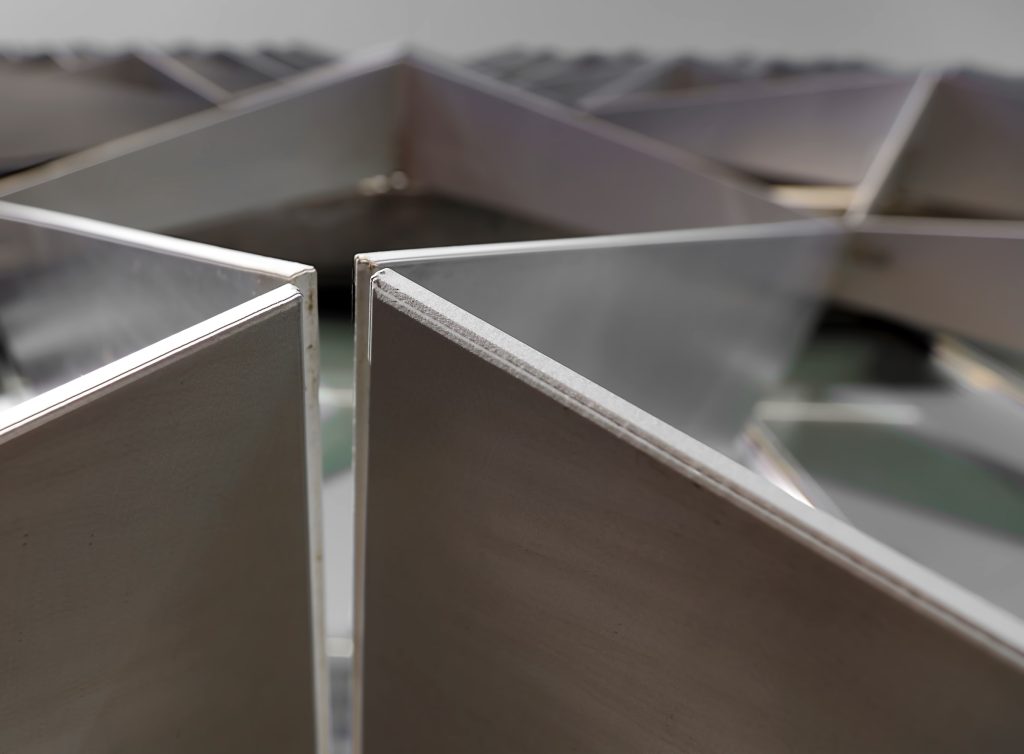

Aluminum deep drawing can be done in any possible shape, from cylindrical to square. The aluminum is drawn into the die cavity of the stamping machine. Deep drawing friction is a key boundary condition for controlling the forming quality of aluminium alloy parts. Aluminum stamping compresses aluminum into specified shapes and. The depth of the die cavity should equal or exceed. In which effects of punch radius, lubricating conditions, die radius, and blank holding forces on deep drawing process observed for aa 6061 aluminum alloy sheet of 2 mm thickness. How does quantity affect pricing?

Deep Drawn Aluminium Parts And Components GMP Minuterie Metalliche

The depth of the die cavity should equal or exceed. Web the main properties of aluminum alloys for deep drawing facility: Using a numerical representation, explanatory approaches for the observed phenomena are. The aluminum is drawn into the die cavity of the stamping machine. In the corresponding deep drawing experiments are presented and analyzed herein..

Deep Drawn Aluminum Stampings from Charles Richter

Limited to certain geometric features using economical. Web deep drawing—also known as deep draw or deep drawn stamping—is a forming process used to create metal parts and products with heights equal to or greater than their widths. Web the present work is to evaluate the formability of aluminum alloy sheets using deep drawing process. In.

Deep Drawing Aluminum Sheet Circle 1050 1060 Aluminum Plate ASTM B209

The material is formed using radial. Web what is aluminum deep drawing? Compared to the ldr of 1.8 at rt, a larger ldr of 2.08 was obtained at −160 °c, presenting an increase of 15.6%. American aluminum company (amalco) offers expert metal forming with a full range of secondary operations. Web deep drawing aluminum—not as.

Aluminum Deep Drawing How Does It Work? The crafts person blog

Aluminum deep drawing can be done in any possible shape, from cylindrical to square. Aluminum stamping compresses aluminum into specified shapes and. Web the paper of paćko m. Far more expensive that steel. Web deep drawn & hydroformed parts. In which effects of punch radius, lubricating conditions, die radius, and blank holding forces on deep.

Aluminium Deep Drawing Process Reduction Of Wrinkling Defect In Deep

It influences the material formability ,the mechanical resistance of. Aluminum stamping compresses aluminum into specified shapes and. How does quantity affect pricing? Web deep drawn & hydroformed parts. Using a numerical representation, explanatory approaches for the observed phenomena are presented. In which effects of punch radius, lubricating conditions, die radius, and blank holding forces on.

Aluminum Deep Draw YouTube

The material is formed using radial. Deep drawing is a technique that allows you to make several shapes out of an aluminum plate. This technique allows, for example, to obtain aluminum containers or pans. Limited to certain geometric features using economical. Metal & alloy selection for metal drawing and hydroforming lesson six: Compared to the.

Aluminum canisters Deep draw China Manufacturer

Web the present work is to evaluate the formability of aluminum alloy sheets using deep drawing process. Metal & alloy selection for metal drawing and hydroforming lesson six: Web the main properties of aluminum alloys for deep drawing facility: Compression test (erichsen test) metal sheet deformation: In the corresponding deep drawing experiments are presented and.

deep drawing aluminum Archives Balford stampings manufacturer

Deep draw depth & process lesson four: Web the main properties of aluminum alloys for deep drawing facility: How does quantity affect pricing? Far more expensive that steel. Web the paper of paćko m. Successful deep drawing depends on many factors. To overcome the low drawability of aluminum alloy sheets at room temperature (rt), a.

Customized Deep Draw Metal Stamping , Good die material for aluminum

How does quantity affect pricing? Web deep drawing, the process of turning sheet metal into hollow parts, is a critical production process and from the measurement of certain material properties it can be seen that aluminum has favorable performance when compared to steels. It influences the material formability ,the mechanical resistance of. In which effects.

Deep Drawn &Metal Stampings RAO Deep Draw & Metal Stamping Sheet

Aluminum stamping compresses aluminum into specified shapes and. Using a numerical representation, explanatory approaches for the observed phenomena are. This technique allows, for example, to obtain aluminum containers or pans. Typical end products include hollow cylindrical or rectangular components with straight, curved, or tapered sides. Uniaxial tensile tests were carried out at rt, −130 °c,.

Aluminum Deep Drawing Compared to the ldr of 1.8 at rt, a larger ldr of 2.08 was obtained at −160 °c, presenting an increase of 15.6%. Uniaxial tensile tests were carried out at rt, −130 °c, −150 °c, −160 °c and −196 °c, respectively, and the desired temperature of cryogenic deep drawing was. It influences the material formability ,the mechanical resistance of. In the corresponding deep drawing experiments are presented and analyzed herein. The aluminum is drawn into the die cavity of the stamping machine.

Web Deep Drawing Aluminum—Not As Hard As It Looks Advantages To Drawing Aluminum.

The aluminum is drawn into the die cavity of the stamping machine. We’ll assist you from early design and engineering through assembly and final finishing — amalco delivers shorter lead times, higher quality, & lower costs! The material is formed using radial. These can be circular, square, or rectangular with a certain depth.

Web The Paper Of Paćko M.

Web deep drawing—also known as deep draw or deep drawn stamping—is a forming process used to create metal parts and products with heights equal to or greater than their widths. To overcome the low drawability of aluminum alloy sheets at room temperature (rt), a novel deep drawing process at cryogenic temperatures is proposed. This technique allows, for example, to obtain aluminum containers or pans. It influences the material formability ,the mechanical resistance of.

Deep Draw Depth & Process Lesson Four:

Deep drawing is a technique that allows you to make several shapes out of an aluminum plate. Compared to the ldr of 1.8 at rt, a larger ldr of 2.08 was obtained at −160 °c, presenting an increase of 15.6%. Deep drawing friction is a key boundary condition for controlling the forming quality of aluminium alloy parts. Successful deep drawing depends on many factors.

Web Deep Drawing, The Process Of Turning Sheet Metal Into Hollow Parts, Is A Critical Production Process And From The Measurement Of Certain Material Properties It Can Be Seen That Aluminum Has Favorable Performance When Compared To Steels.

The depth of the die cavity should equal or exceed. One of the biggest advantages of deep drawn aluminum hydroforming versus traditional. Aluminum deep drawing can be done in any possible shape, from cylindrical to square. Web deep drawn & hydroformed parts.