Calculating Chip Load

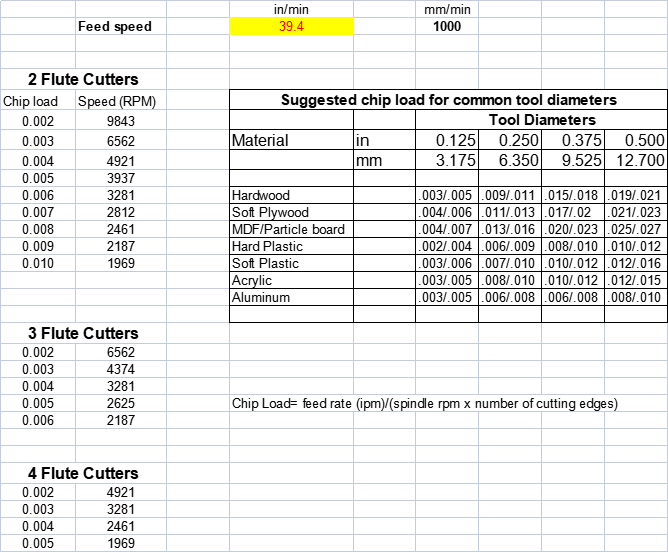

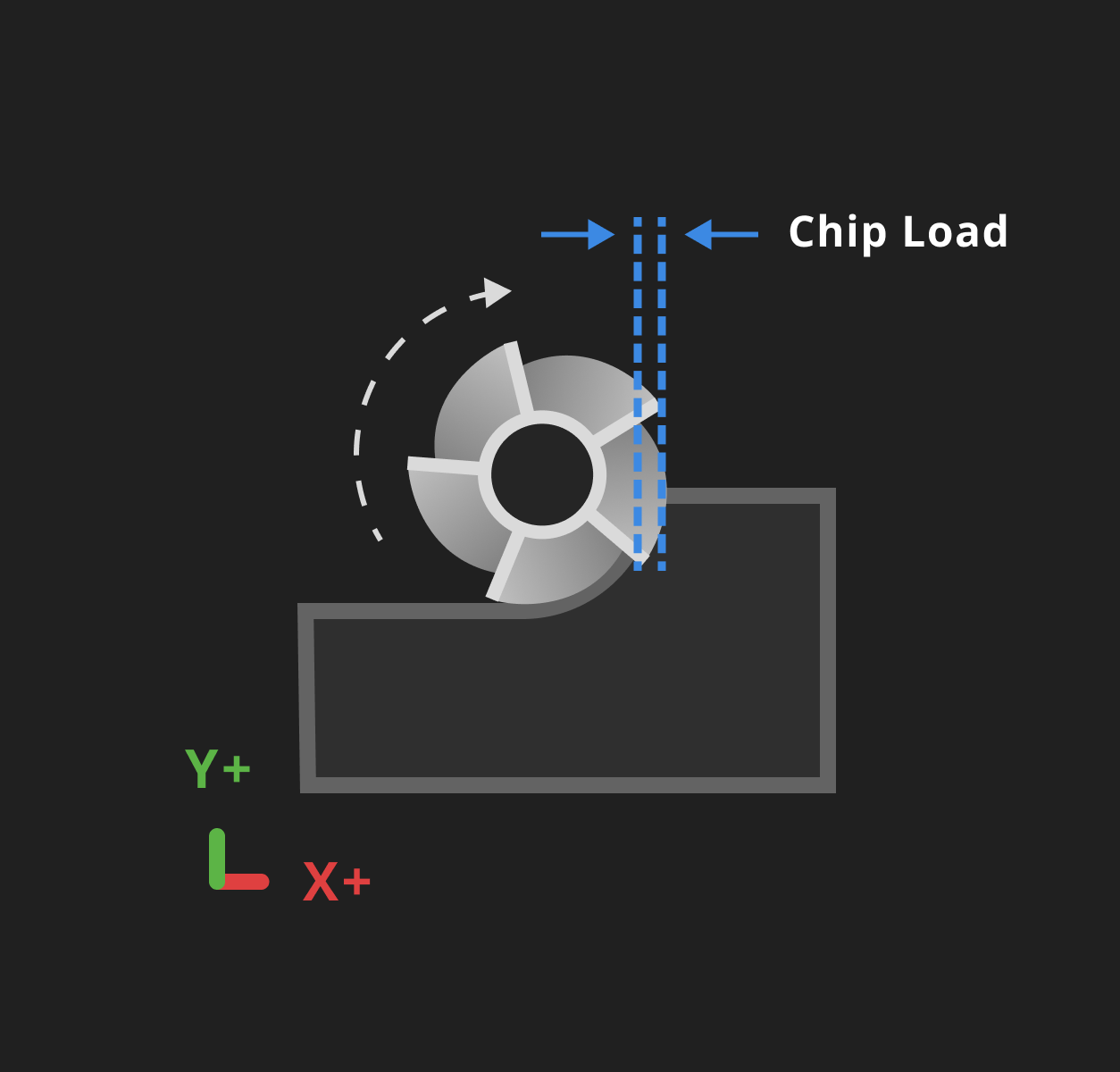

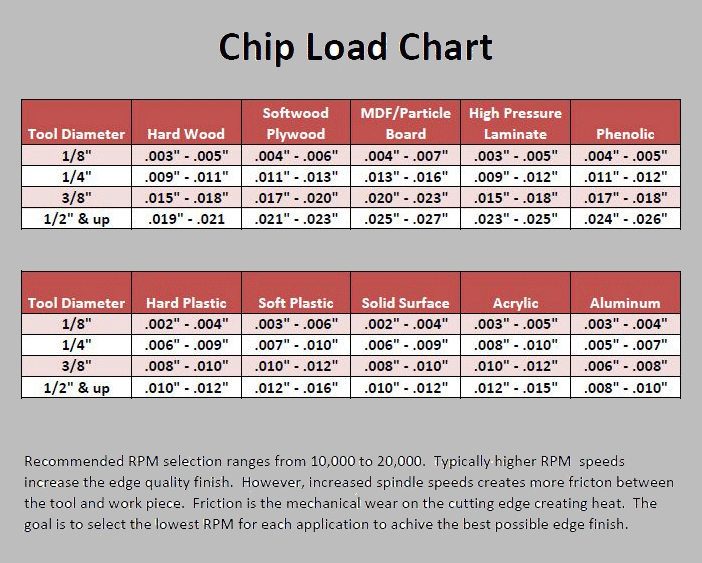

Calculating Chip Load - Depend on material and tool diameter. Web in order to achieve accuracy and precision when calculating speed and feeds with a chip load chart, spindle speed needs to be carefully controlled. Web chip load per tool is the appropriate amount of material removed by all cutting edges on a tool in a single revolution. Chip load, also known as feed per tooth, is the amount of material removed by each cutting edge of a cutting tool in a single revolution. Web here’s a useful formula:

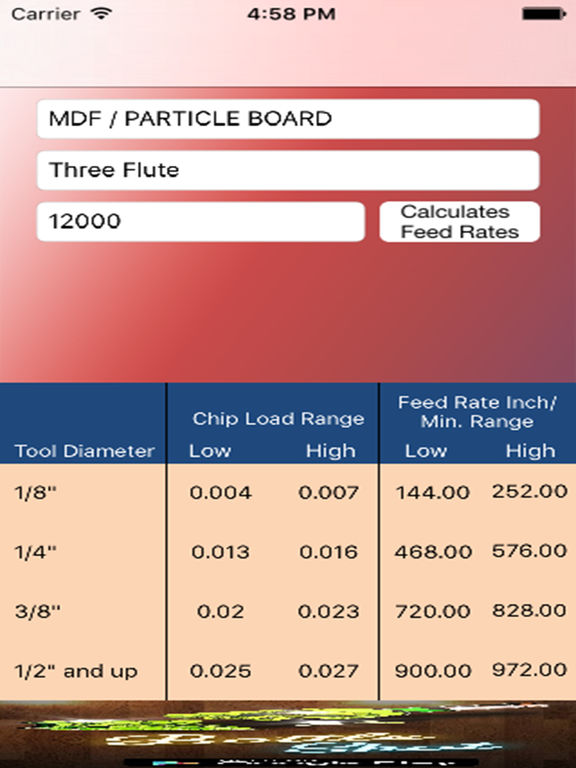

Web calculating the chip load involves using a simple formula: Chip load (cl) = feed rate (fr) / (spindle speed (ss) × number of cutting edges) to calculate the. Web here’s a useful formula: Depend on material and tool diameter. This is measured in inches per revolution (ipr). Web chip load per tool is the appropriate amount of material removed by all cutting edges on a tool in a single revolution. Web cutting speed and chip load:

Calculate CNC Speeds and Feeds with Suggested Chip Load for Common Too

Chip load = feed rate (inches per minute) / (rpm x number of. This is measured in inches per revolution (ipr). Web updated november 3, 2023. Increase feed rate decrease rpm use a cutter with fewer flutes to. Web the milling speed and feed calculator automatically calculated the right feed to keep the desired chip.

What is your current chip load? How do you calculate it? Scarlett, Inc.

Web what is chip load? The feed rate of the material past the cutting edges. The rotation speed of the tool. Chip load = feed rate (inches per minute) / (rpm x number of. Web chip load per tool is the appropriate amount of material removed by all cutting edges on a tool in a.

Bantam Tools Blog — What is Chip Load & Why It’s Important

The rotation speed of the tool. Web updated november 3, 2023. Web the calculation is simple: Chip load, also known as feed per tooth, is the amount of material removed by each cutting edge of a cutting tool in a single revolution. Chip load = feed rate (inches per minute) / (rpm x number of..

Hall Manufacturing Solutions

Chip load = feed rate (inches per minute) / (rpm x number of flutes). Chip thickness per tooth while cnc feed rates are specified in length units. The chip load calculator on the right shows the the optimal feed rate for your entered. Web 4 rows calculation are as follows: Chip load = feed rate/.

Chip Load Guide for Beginners MellowPine

[ cl = \frac {feed \ rate (f)} {cutting \ speed (s) \times number \ of \ cutting \ edges (z)} ] benefits of using chip load calculators: Chip load = feed rate (inches per minute) / (rpm x number of flutes). Chip thickness per tooth while cnc feed rates are specified in length units..

Feed Speed Chip Load 3 EdwoodCrafting

Web calculating the chip load involves using a simple formula: Web updated november 3, 2023. Use the calculator to determine approximate settings. Web peak toolworks chip load calculator makes it easy to determine feed speed, knife marks per inch and chip load per tooth. Web the formula for chip load (cl) is given by: Ipt.

Bantam Tools Blog — What is Chip Load & Why It’s Important

Web peak toolworks chip load calculator makes it easy to determine feed speed, knife marks per inch and chip load per tooth. The number of cutting edges on the tool. Web updated november 3, 2023. Web here’s a useful formula: Web what is chip load? Chip load, also known as feed per tooth, is the.

App Shopper CNC Chip Load Calculator (Utilities)

Chip load = feed rate (inches per minute) / (rpm x number of flutes). Chip thickness per tooth while cnc feed rates are specified in length units. This is measured in inches per revolution (ipr). Ipt (inches / tooth) chip load = feed rate / (rpm x number of teeth) chip load: Web feed rate.

CNC Easy calculate Chip Load, Feedrate, RPM for your endmill YouTube

Web bantam tools blog — what is chip load & why it’s important optimizing for chip load improves cut efficiency, the lifespan of your tooling and your. Web feed rate = spindle speed (rpm) * number of flutes * chip load (inches) = spindle speed * number of flutes * chip load = answer inches/min..

Chip Load Calculator Easy and Accurate MellowPine

The number of cutting edges on the tool. Web in order to achieve accuracy and precision when calculating speed and feeds with a chip load chart, spindle speed needs to be carefully controlled. For example, if the chip load is 500 ipm / (15,000 rpm x 2 flutes). How knives dull when an insert knife..

Calculating Chip Load Chip load = feed rate (inches per minute) / (rpm x number of flutes). Web peak toolworks chip load calculator makes it easy to determine feed speed, knife marks per inch and chip load per tooth. Web calculating the chip load involves using a simple formula: Use the calculator to determine approximate settings. Web 4 rows calculation are as follows:

It Helps Determine The Thickness Of Material Removed By Each.

Chip load, also known as feed per tooth, is the amount of material removed by each cutting edge of a cutting tool in a single revolution. The feed rate of the material past the cutting edges. Web chip load per tool is the appropriate amount of material removed by all cutting edges on a tool in a single revolution. Ipt (inches / tooth) chip load = feed rate / (rpm x number of teeth) chip load:

Web The Milling Speed And Feed Calculator Automatically Calculated The Right Feed To Keep The Desired Chip Load.

Use the calculator to determine approximate settings. Web in order to achieve accuracy and precision when calculating speed and feeds with a chip load chart, spindle speed needs to be carefully controlled. Web feed rate = spindle speed (rpm) * number of flutes * chip load (inches) = spindle speed * number of flutes * chip load = answer inches/min. Web peak toolworks chip load calculator makes it easy to determine feed speed, knife marks per inch and chip load per tooth.

Number Of Teeth (Or Flutes):

Chip load = feed rate (inches per minute) / (rpm x number of flutes). Chip load (cl) = feed rate (fr) / (spindle speed (ss) × number of cutting edges) to calculate the. How knives dull when an insert knife. Web what is chip load?

Web The Formula For Chip Load (Cl) Is Given By:

Increase feed rate decrease rpm use a cutter with fewer flutes to. Chip load = feed rate (inches per minute) / (rpm x number of. Web bantam tools blog — what is chip load & why it’s important optimizing for chip load improves cut efficiency, the lifespan of your tooling and your. Chip load in ipt per milling cutter diameter and workpiece material tap the icons to view the chip load of more raw materials see more