Chip Load Calculator

Chip Load Calculator - Web use this tool to calculate the chip load, spindle speed, xy feed rate, plunge rate and stepover of your tool based on tool geometry, processing parameters and material. Simply put, chip load is the size/thickness of the chip being removed per flute/cutting edge with every revolution of the tool. Setting machining parameters to ensure optimal chip load improves machining quality. Web correct “chip load”, is important. So, going from a 2.

So, going from a 2. Web calculation are as follows: Web correct “chip load”, is important. These tools take into account various factors such as cutting speed, feed. Web how do you calculate speed and feed? Web the combination of three factors will affect the life of the cutting tools before renewal of the edge (either by replacing an insert knife, or having a fixed tool resharpened). Web this is determined by how fast the cutter is moving forward into the material and how fast it is turning (chip load = feed rate / [rpm x number of flutes]).

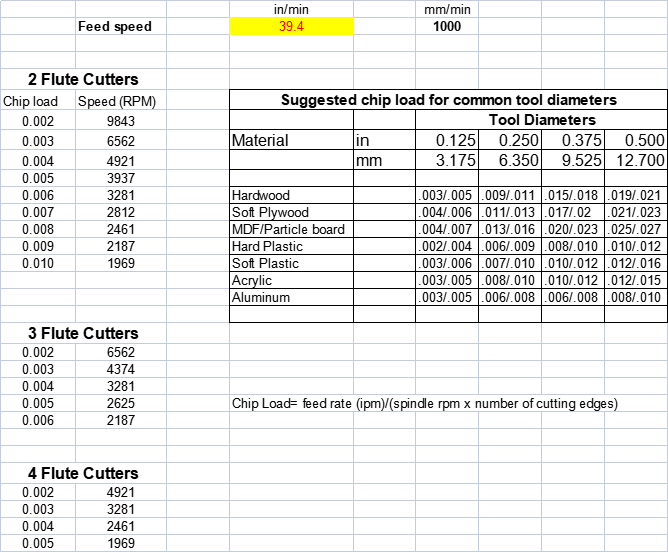

Calculate CNC Speeds and Feeds with Suggested Chip Load for Common Too

Web this is determined by how fast the cutter is moving forward into the material and how fast it is turning (chip load = feed rate / [rpm x number of flutes]). Web to achieve optimal chip load, machinists and cnc operators rely on chip load calculators. Calculating chip load accurately is essential for. Web.

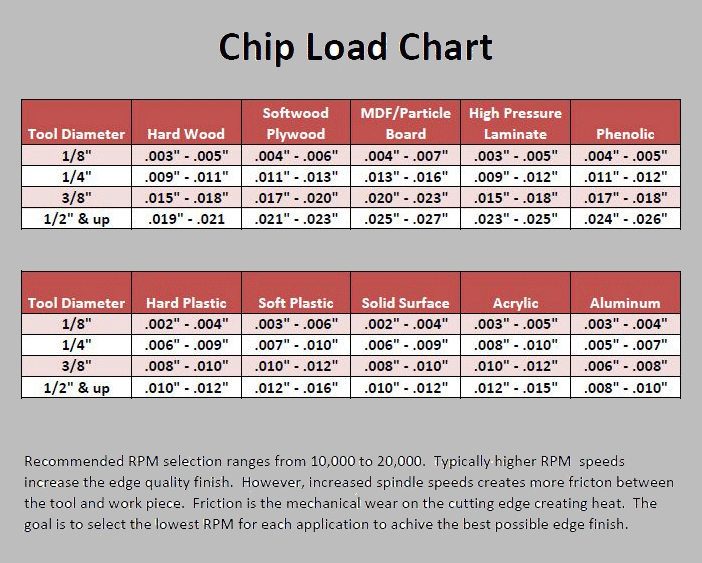

Chip Load Guide for Beginners MellowPine

Metal removal rate per minute. Learn how to adjust feed rate, chip load, spindle speed, and power based. Formulas and explanations for different cases. Web chip thinning calculator radial and axial chip thinning calculators. Web the speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on.

CNC Chip Load Calculator by Maulik Jadvani

Web learn how to use the chip load calculator to optimize your cnc machining processes by calculating the chip load per tooth. Web the speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of the parameters you have currently set. Chip load =.

Chip Load Calculator Easy and Accurate MellowPine

*the rpm and chip load that automatically populates in this calculator are the. Ipm (inches / minute) spindle speed: Web radial chip thinning calculator cutter diameter [d}* radial depth of cut [ae]* axial chip thinning calculator select milling cutter shape 90° chamfer and feedmills ballnose. Web the combination of three factors will affect the life.

CNC Easy calculate Chip Load, Feedrate, RPM for your endmill YouTube

Web how do you calculate speed and feed? Web a free tool to help you optimize cnc router and spindle settings for different types of cuts. The chip load calculator on the right shows the the optimal feed rate for your entered chip. Web chip load is the depth of cut for each tooth on.

Formulas How to Calculate the Chip Load Per Tooth (CLPT) R

Web the speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of the parameters you have currently set. Web how do you calculate speed and feed? Ipt (inches / tooth) chip. Simply put, chip load is the size/thickness of the chip being removed.

Hall Manufacturing Solutions

Web learn how to use the chip load calculator to optimize your cnc machining processes by calculating the chip load per tooth. Web calculate chip load, feed, rotation, and other parameters for various machining operations using imperial or metric units. Web the chip load calculator on the left is used when you have a target.

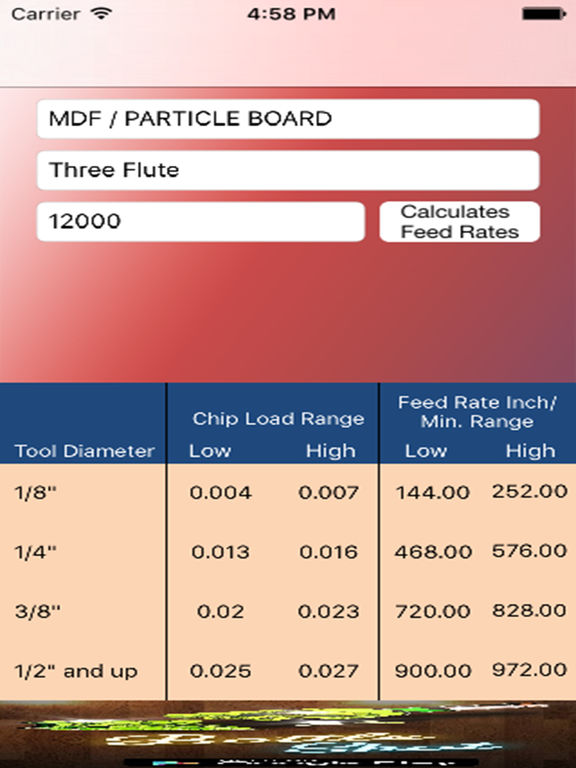

App Shopper CNC Chip Load Calculator (Utilities)

Web the chip load calculator on the left is used when you have a target chip load in mind. Web learn how to use the chip load calculator to optimize your cnc machining processes by calculating the chip load per tooth. So, going from a 2. Ipt (inches / tooth) chip. Ipm (inches / minute).

Precise Pro/Calc Material Directory Spindles Speed Chip Load & Feed

Web chip load is the depth of cut for each tooth on a milling cutter. Web this is determined by how fast the cutter is moving forward into the material and how fast it is turning (chip load = feed rate / [rpm x number of flutes]). Learn how to adjust feed rate, chip load,.

App Shopper CNC Chip Load Calculator (Utilities)

Chip load = 500 inches per minutes / (15,000 rpm x 2 flutes) chip. Web chip load is the depth of cut for each tooth on a milling cutter. Web the speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of the parameters.

Chip Load Calculator Choose from a range of tools, such as surface feet per. Chip load = feed rate (inches per minute) / (rpm x number of flutes). Web use this tool to calculate the chip load, spindle speed, xy feed rate, plunge rate and stepover of your tool based on tool geometry, processing parameters and material. Calculating chip load accurately is essential for. Web chip thinning calculator radial and axial chip thinning calculators.

Web Calculate Chip Load, Feed, Rotation, And Other Parameters For Various Machining Operations Using Imperial Or Metric Units.

Chip load calculator get chip load. Web the chip load calculator on the left is used when you have a target chip load in mind. Web calculation are as follows: Web correct “chip load”, is important.

Web Radial Chip Thinning Calculator Cutter Diameter [D}* Radial Depth Of Cut [Ae]* Axial Chip Thinning Calculator Select Milling Cutter Shape 90° Chamfer And Feedmills Ballnose.

So, going from a 2. Calculating chip load accurately is essential for. Ipm (inches / minute) spindle speed: Choose from a range of tools, such as surface feet per.

Simply Put, Chip Load Is The Size/Thickness Of The Chip Being Removed Per Flute/Cutting Edge With Every Revolution Of The Tool.

Web a free tool to help you optimize cnc router and spindle settings for different types of cuts. The chip load calculator on the right shows the the optimal feed rate for your entered chip. Chip load = 500 inches per minutes / (15,000 rpm x 2 flutes) chip. Ipt (inches / tooth) chip.

Web Use This Tool To Calculate The Chip Load, Spindle Speed, Xy Feed Rate, Plunge Rate And Stepover Of Your Tool Based On Tool Geometry, Processing Parameters And Material.

Web this is determined by how fast the cutter is moving forward into the material and how fast it is turning (chip load = feed rate / [rpm x number of flutes]). Web learn how to use the chip load calculator to optimize your cnc machining processes by calculating the chip load per tooth. Number of teeth (or flutes): Formulas and explanations for different cases.