Deep Draw Stampings

Deep Draw Stampings - Deep drawn stamping refers to the process of forming sheet metal under compressive and tensile conditions. Web deep drawn stamping benefits of deep drawn stamping. This is an economical alternative for customers as the faster speeds and higher production rates often offset the original costs of tooling. Aqueous cleaning, deburring, heat treating, and passivation. From the initial quote through production, our toolmakers, engineers, quality staff, and supply chain providers work concurrently to assure the best course for your deep draw components.

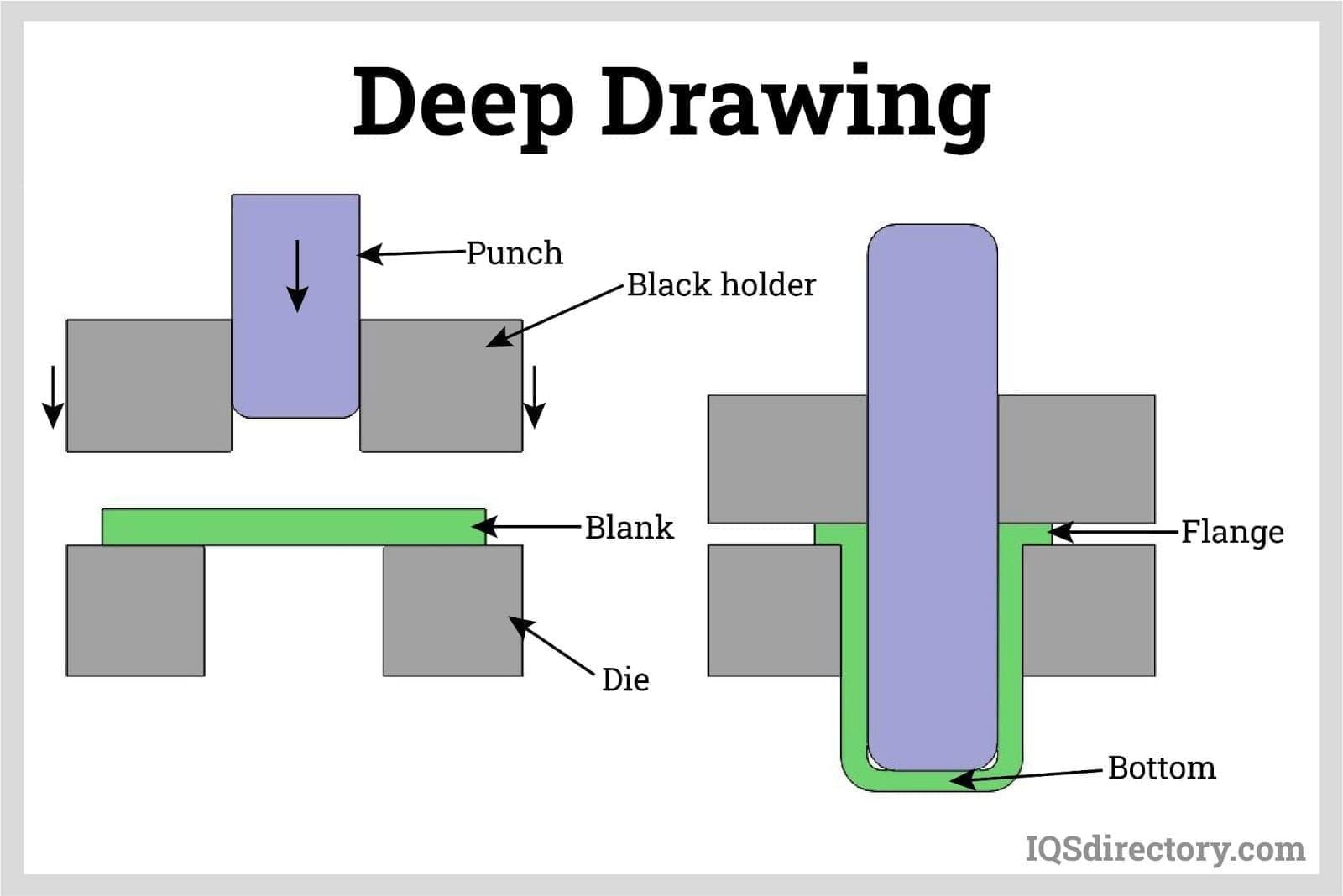

Aerospace energy storage medical products military & defense oil & gas semiconductor aerospace Web home » eyelets & deep drawn stampings » deep drawing deep drawing deep drawing is a type of metal forming process where parts are produced by punching sheet metal into a formed die. · parts that must be produced to tight tolerances. Cylindrical deep drawn aluminum cans are typical deep drawing applications. Considerations for deep drawn stamping. Web welcome to our deep draw shop. The open communication between our team and yours.

Deep Drawn &Metal Stampings RAO Deep Draw & Metal Stamping Sheet

This is an economical alternative for customers as the faster speeds and higher production rates often offset the original costs of tooling. Web proudly made in the usa. Cutting a round or shaped section of metal from the draw component. Web welcome to our deep draw shop. The benefit of using deep drawn metal stampings.

Deep Draw Metal Stamping Getting Started

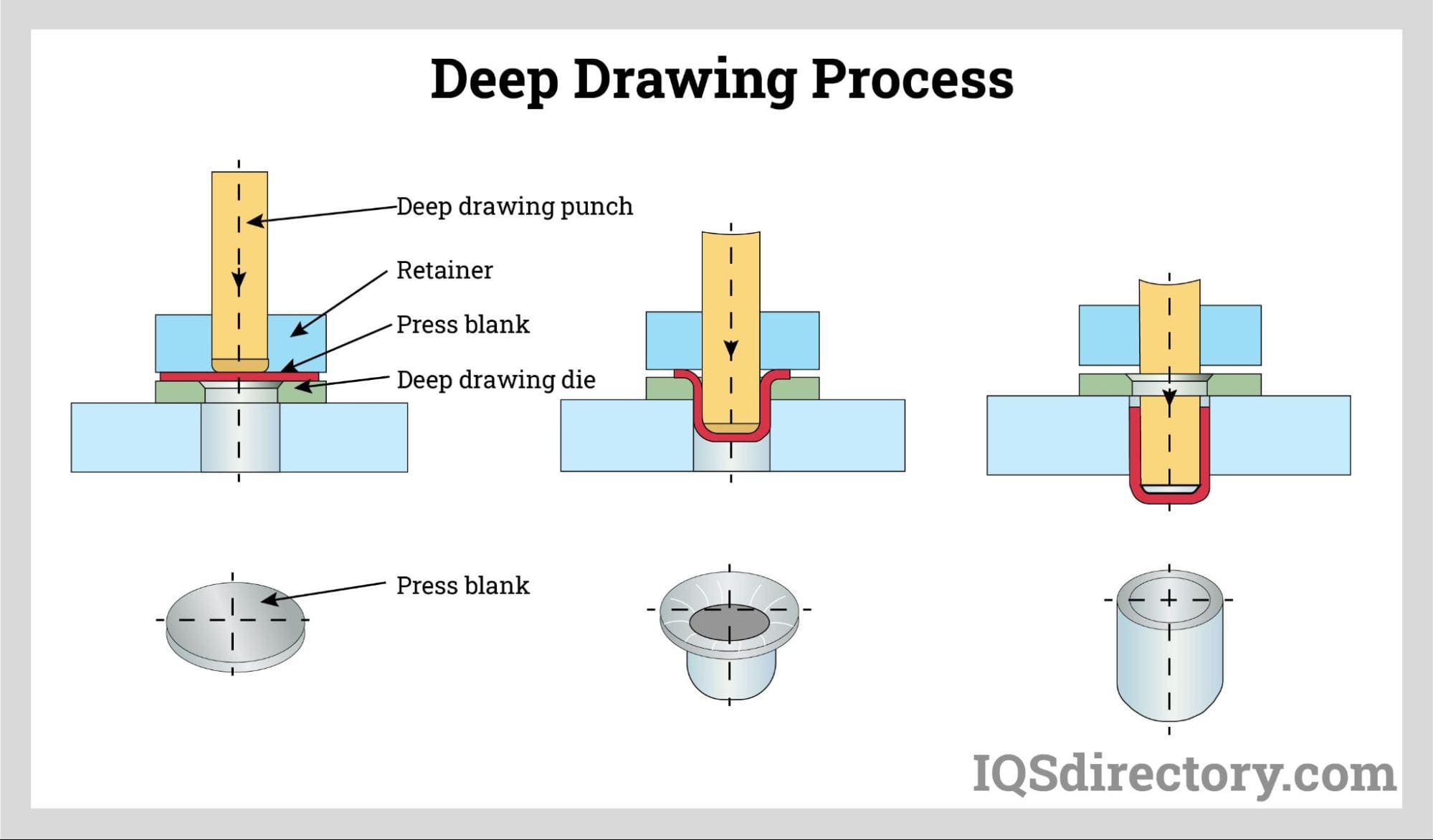

· parts that must be produced to tight tolerances. This is accomplished by drawing a flat metal blank into a die cavity (or several cavities in a series of steps) with a punch until the metal has been shaped into the desired form. We provide superior value when compared to suppliers in china, india, or.

Deep Draw Metal Stampings & Formed Parts Hudson Technologies

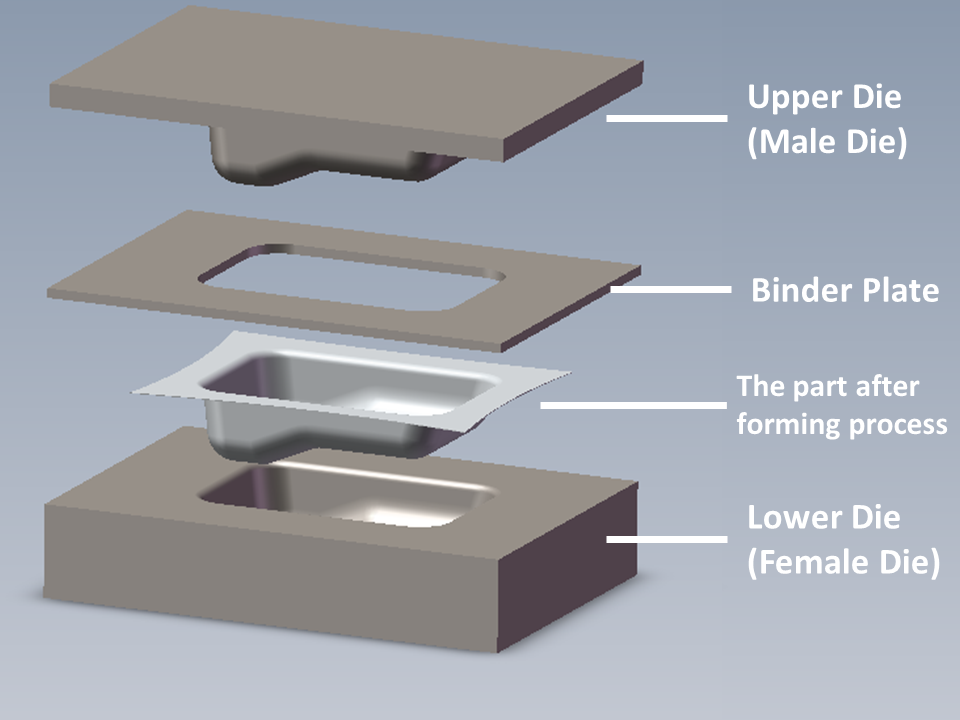

Metal stamping has high accuracy and can be set to tolerances as low as ±.0005 in. Anatomy of deep drawn stamping. Web deep draw stamping is a machining process that process a flat blanking strip with a certain shape obtained after punching into various open hollow parts or reduces the diameter of the open hollow.

Deep Draw Stamping D&H Industries

Web top deep drawn stamping services: Web deep draw stamping is a machining process that process a flat blanking strip with a certain shape obtained after punching into various open hollow parts or reduces the diameter of the open hollow parts and increases the height. This is accomplished by drawing a flat metal blank into.

Deep Draw Metal Stampings & Formed Parts Hudson Technologies

· parts that must be produced to tight tolerances. What are the types of deep drawing processing? Metal stamping has high accuracy and can be set to tolerances as low as ±.0005 in. Web welcome to our deep draw shop. Web deep draw stamping works quickly and efficiently once it has been set up, making.

Metal Prototype Stamping Deep Drawn Prototypes Rapid Prototyping

Examples of typical deep drawn components include cans, housings, and other containers. This is accomplished by drawing a flat metal blank into a die cavity (or several cavities in a series of steps) with a punch until the metal has been shaped into the desired form. Web deep drawn stamping process the process. This is.

Hot Stamping and Prototype Stamping Duggan Manufacturing

Starbucks · tools · united states · promotions Metal stamping has high accuracy and can be set to tolerances as low as ±.0005 in. Considerations for deep drawn stamping. Web deep drawn stamping benefits of deep drawn stamping. Cylindrical deep drawn aluminum cans are typical deep drawing applications. Deep drawn stamping offers numerous advantages over.

Deep Drawn Stamping Companies Deep Drawn Stamping Services

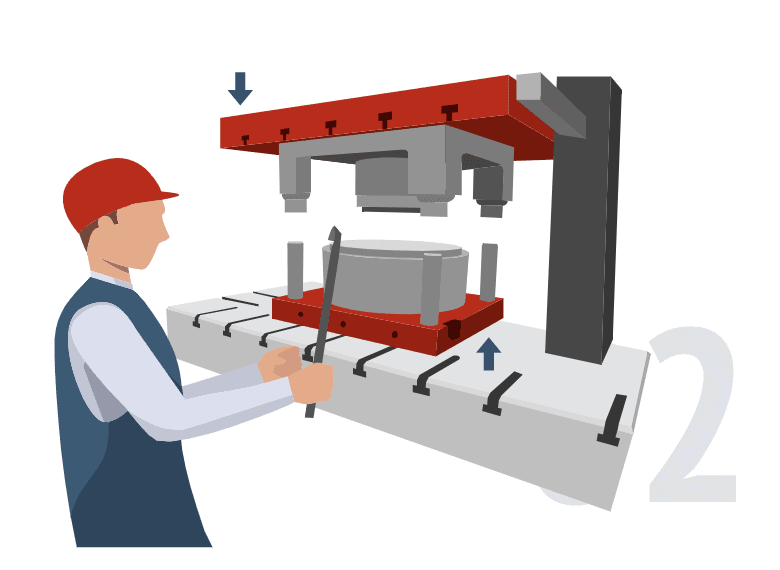

Web deep draw metal stamping requires the use of hardened steel dies to accommodate higher production volumes. Cylindrical deep drawn aluminum cans are typical deep drawing applications. Prospect machine products deep draw metal stamping. Starting out with only two presses, pat thompson built the company on a simple premise: From the initial quote through production,.

Deep Drawn Stamping Services at Manor Tool & Manufacturing

For 75 years, the national die company has been dedicated to manufacturing the best deep drawn stampings and parts and providing the highest level of customer service, while supporting our domestic job market. The hines group is a u.s. Web proudly made in the usa. Examples of typical deep drawn components include cans, housings, and.

Deep Drawn Stamping Companies Deep Drawn Stamping Services

The benefit of using deep drawn metal stampings is the creation of a seamless metal component. For 75 years, the national die company has been dedicated to manufacturing the best deep drawn stampings and parts and providing the highest level of customer service, while supporting our domestic job market. At jones metal, we work to.

Deep Draw Stampings Web deep draw stamping is a machining process that process a flat blanking strip with a certain shape obtained after punching into various open hollow parts or reduces the diameter of the open hollow parts and increases the height. Here at pmp, we tailor our deep drawing expertise in our metal forming technology to our customers’ needs & best practices. · parts that must be produced to tight tolerances. Globalspec.com has been visited by 10k+ users in the past month Web proudly made in the usa.

What Are The Types Of Deep Drawing Processing?

Here at pmp, we tailor our deep drawing expertise in our metal forming technology to our customers’ needs & best practices. Metal stamping has high accuracy and can be set to tolerances as low as ±.0005 in. Anatomy of deep drawn stamping. Web home » eyelets & deep drawn stampings » deep drawing deep drawing deep drawing is a type of metal forming process where parts are produced by punching sheet metal into a formed die.

Aqueous Cleaning, Deburring, Heat Treating, And Passivation.

The open communication between our team and yours. The most prominent benefit is that the unit cost is decreased considerably when unit count increases. For 75 years, the national die company has been dedicated to manufacturing the best deep drawn stampings and parts and providing the highest level of customer service, while supporting our domestic job market. Prospect machine products deep draw metal stamping.

Web Deep Draw Metal Stamping Is A Processing Method For Making Open Hollow Parts From Flat Material Or Hollow Process Parts By Using A Deep Drawing Die Under The Pressure Of Press.

Web deep draw stamping metal stamping progressive die tooling transfer press tooling metal to rubber and metal to metal tooling for diaphragms custom tooling to meet your exact specifications. Examples of typical deep drawn components include cans, housings, and other containers. Displacing the material to create smaller or larger diameters than the part’s original diameter. Web top deep drawn stamping services:

Forcing Part Of The Components Diameter To Extend From The Original Shape.

· parts that must be produced to tight tolerances. Cylindrical deep drawn aluminum cans are typical deep drawing applications. At jones metal, we work to ensure that deep draw metal stamping is an economical option for. Starting out with only two presses, pat thompson built the company on a simple premise: