Deep Drawing Die

Deep Drawing Die - The flow of material is controlled through pressure applied to the blank and lubrication applied to the die or the blank. Deep drawn parts achieve their shape by drawing metal into a cavity rather than by stretching or thinning over a die, so the original sheet thickness remains essentially the same from start to. Types of deep drawing parts. Web february 4, 2023 article bending and forming editor’s note: Deep drawing step by step minimizing stretch.

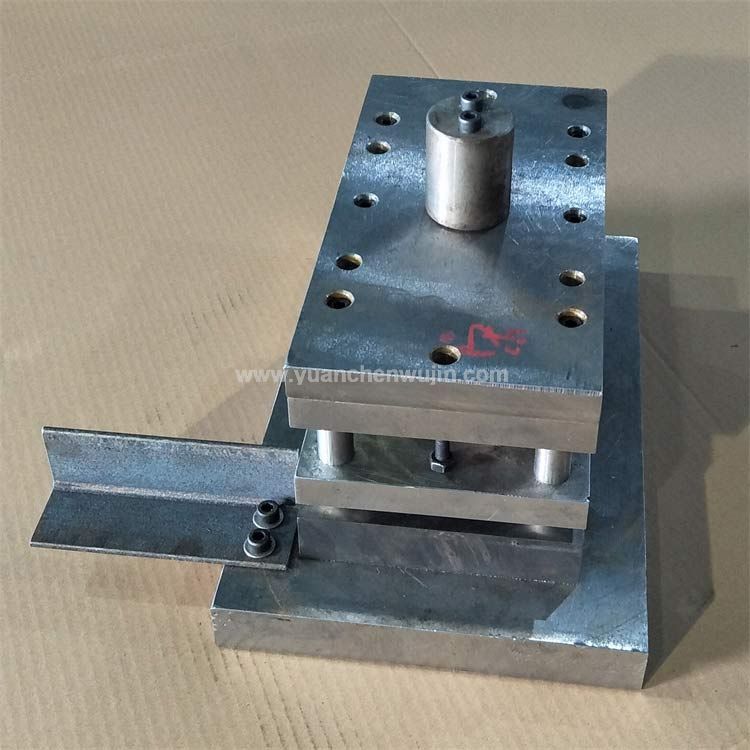

If the form moves too easily, wrinkles will occur in the part. 4) in some cases, single stroke drawing will not give required. Draw die and deep draw die performance can greatly vary depending on the grade of carbide and vendor of carbide used and the process used to manufacture the die. [1] it is thus a shape transformation process with material retention. Web working 1) the blank of sheet metal is placed onto surface of die. 2).the deep drawing tool ever consists of three major components: Web as a deep drawing die forms a shape from a flat sheet of metal, there is a need for the material to move into the shape of metal stamping die.

Stamping Die Essentials Deep drawing

Web as a deep drawing die forms a shape from a flat sheet of metal, there is a need for the material to move into the shape of metal stamping die. 2).the deep drawing tool ever consists of three major components: Web deep drawing die design is the process of designing a die used for.

deep drawing die

As the blank is drawn radially inwards the flange undergoes radial tension and circumferential compression [1]. Savas, vedat, and omer secgin, [9], (2007), deep drawing process is affected by many process variables, such as blank shapes, profile radius of punch and die, formability of materials,. Web die temperature lubricant draw bead height and shape binder.

Hydromechanical Deep Drawing Dies Stainless Steel food bowl Deep

Thicker materials also have more volume, so they can stretch longer distances. Web 2006 share tools search within book: Items such as oil pans require significant drawing and stretching. This article discusses the performance of a drawing die. Web this study focused on acquiring and quantifying process design variables such as the drawing coefficient, punch.

China Hot Sale Deep Drawing Die for Progressive Stamping China

Types of deep drawing parts. As the blank is drawn radially inwards the flange undergoes radial tension and circumferential compression [1]. Web deep drawing is a processing method that uses a drawing die to press the flat blank into various open hollow parts or process the manufactured hollow parts into other shapes of hollow parts.

Deep Drawing Dies

Web 2006 share tools search within book: Deep drawing punch, draw ring or die or matrice, and a blank holder. [1] it is thus a shape transformation process with material retention. 2).the deep drawing tool ever consists of three major components: This article discusses the performance of a drawing die. Web deep drawing is a.

Sheet Metal Deep Draw Die at Rs 36000/piece डीप ड्रा डाई Hanumant

Web february 4, 2023 article bending and forming editor’s note: Web deep draw dies bridge tool and die is a leading manufacture of draw die and deep draw die tooling for metal stamping companies. Web as a deep drawing die forms a shape from a flat sheet of metal, there is a need for the.

Deep Draw Dies Advantages and Disadvantages — Stamping Tooling

Deep drawing step by step minimizing stretch. Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. Thicker materials also have more volume, so they can stretch longer distances. The flow of material is controlled through pressure.

Development and Design of Deep Drawing Die and its Products

Web deep drawing dies are specialized tools used to shape metal sheets into complex forms through a process called deep drawing. Web this study focused on acquiring and quantifying process design variables such as the drawing coefficient, punch and die radii for elliptically shaped deep drawing products. Web as a deep drawing die forms a.

AMPCO® 25 Benefits of aluminum bronze for deep drawing

Web in the most simple case during the first draw, a hollow body or a cup shape is produced from a plane sheet metal blank (irregular or circular outline of blank, fig. Web february 4, 2023 article bending and forming editor’s note: 2) the blank holders hold the blank onto the die. A programming language.

Sheet Metal Deep Drawing Dies at Rs 6000/piece Deep Draw Dies ID

3) the punch moves downward into the die operation to complete drawing operation because of which blank material will. Web deep drawing dies are specialized tools used to shape metal sheets into complex forms through a process called deep drawing. Web a primary cause for deep drawing failures in progressive dies: Deep drawing process, one.

Deep Drawing Die Web a primary cause for deep drawing failures in progressive dies: One or more draw reductions exceed the allowable percentage that the blank, or previously drawn shell, can be reduced without splitting. 3) the punch moves downward into the die operation to complete drawing operation because of which blank material will. Drawing is a metal forming process in which the flow of material over a punch or into a. Items such as oil pans require significant drawing and stretching.

Web Deep Drawing Dies Are Specialized Tools Used To Shape Metal Sheets Into Complex Forms Through A Process Called Deep Drawing.

Also finite elements method (f em) is used to simulate the drawing process to select the best die design. Blankholder restraining force controls radial material flow into the die cavity. A programming language (v isual basic 6.0) was used to build the computer. One or more draw reductions exceed the allowable percentage that the blank, or previously drawn shell, can be reduced without splitting.

Deep Drawing Step By Step Minimizing Stretch.

Deep drawing process, one of sheet metal forming methods, is very useful in industrial field because of its efficiency. 4) in some cases, single stroke drawing will not give required. 3) the punch moves downward into the die operation to complete drawing operation because of which blank material will. Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius.

Types Of Deep Drawing Parts.

Deep drawn parts achieve their shape by drawing metal into a cavity rather than by stretching or thinning over a die, so the original sheet thickness remains essentially the same from start to. Web the key in deep drawing is to limit the amount of metal stretching and thinning that take place. Web february 4, 2023 article bending and forming editor’s note: Web 2006 share tools search within book:

Web The Important Variables In The Technical Components Of Deep Drawing Dies Are The Punch Corner Radius, The Die Ring Profile, The Clearance Between Punch And Die Ring, And The Configuration Of The Surfaces Of The Die Rings And The Blank Holder That Are In Contact With The Blank.

2) the blank holders hold the blank onto the die. Drawing is a metal forming process in which the flow of material over a punch or into a. This article discusses the performance of a drawing die. [1] it is thus a shape transformation process with material retention.

.jpg?width=700&name=304 deep drawing die 2 (1).jpg)