How To Calculate Min Max Inventory Levels

How To Calculate Min Max Inventory Levels - Level of stock = reorder level (avg. It’s based on your purchase and sales cycles, and it varies by product. Example of how to calculate optimal inventory level. Web introduction calculating min max inventory levels is essential for businesses to efficiently manage their stock and avoid overstocking or stockouts. Reorder point (rop) = demand during lead time × lead time in days.

Web min/max inventory method by joannes vermorel, october 2014 the min/max inventory ordering method is a basic reordering mechanism that is supported by many erps and. Web how to calculate your min/max inventory levels 1) projected usage rate: Web you can plug this data into the following formula to calculate your min inventory level: We will begin by constructing a. Reorder point = safety stock + (average daily demand × lead time) safety. Level of stock = reorder level (avg. Example of how to calculate optimal inventory level.

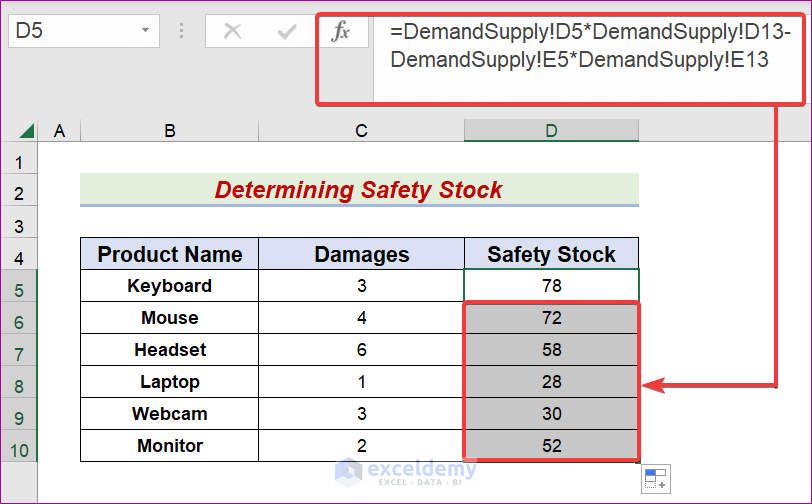

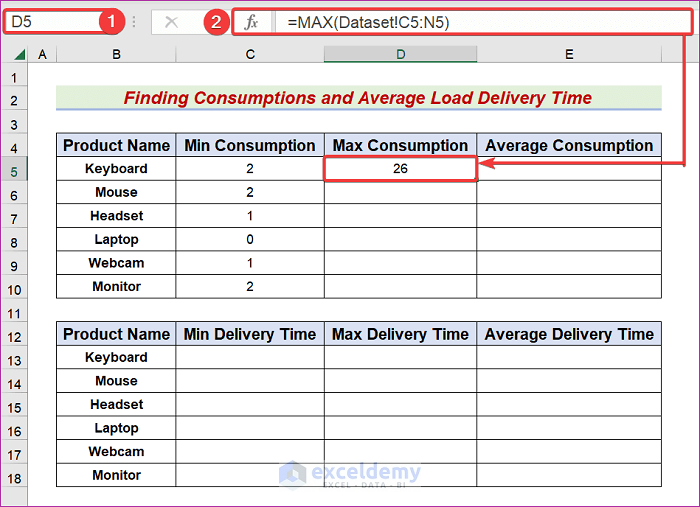

Min Max Inventory Calculation in Excel (with Easy Steps)

Web how to calculate your min/max inventory levels 1) projected usage rate: Reorder point (rop) = demand during lead time × lead time in days. Web min/max inventory method by joannes vermorel, october 2014 the min/max inventory ordering method is a basic reordering mechanism that is supported by many erps and. Web how to calculate.

Min Max Inventory Calculation in Excel (with Easy Steps)

Web today, we’ll dive into how you can set the right inventory levels based on your supply chain lead times and product sales behavior, dig into the best ways to view. There are two lines a. Web you can plug this data into the following formula to calculate your min inventory level: It accounts for.

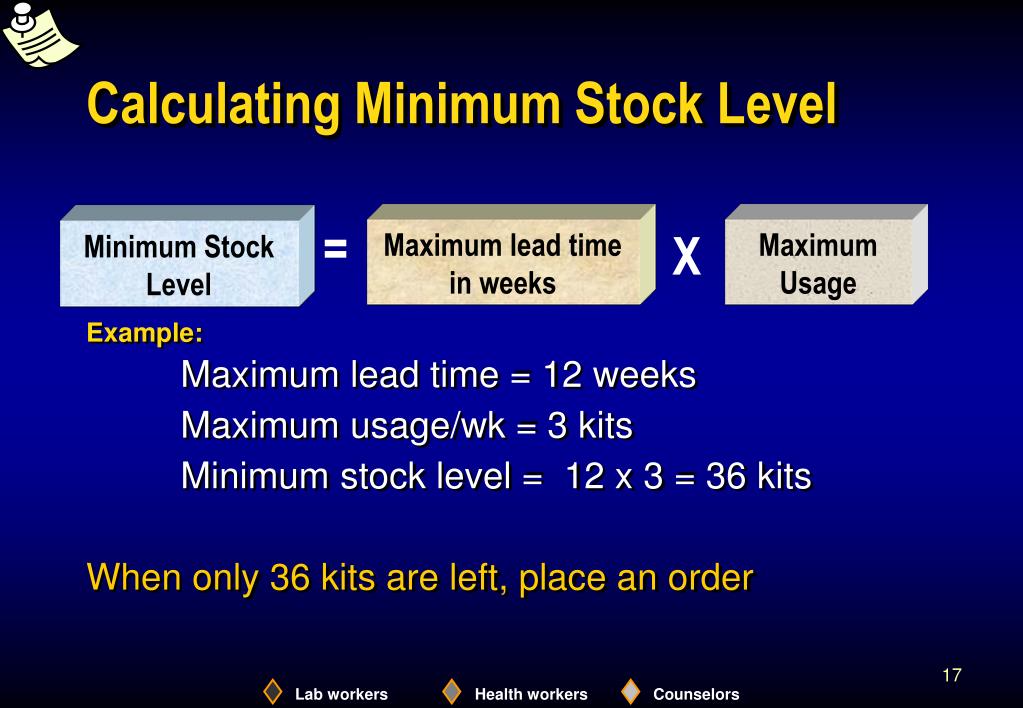

PPT Module 10 Inventory PowerPoint Presentation, free download ID

Web explore the significance of inventory levels, learn methods to calculate and maintain optimal inventory levels, and enhance your business efficiency with priceva. Web today, we’ll dive into how you can set the right inventory levels based on your supply chain lead times and product sales behavior, dig into the best ways to view. Web.

Set up Min/Max Inventory Levels

It accounts for any unforeseen spikes in demand, allows companies to capture. Level of stock = reorder level (avg. However, once you have a handle on the patterns of a. Web you can plug this data into the following formula to calculate your min inventory level: Web explore the significance of inventory levels, learn methods.

Min Max Inventory Calculation in Excel (with Easy Steps)

The projected usage rate is the average amount of inventory that you expect to sell. Web min/max inventory method by joannes vermorel, october 2014 the min/max inventory ordering method is a basic reordering mechanism that is supported by many erps and. Web introduction calculating min max inventory levels is essential for businesses to efficiently manage.

Min Max Inventory Calculation in Excel (with Easy Steps)

Web introduction calculating min max inventory levels is essential for businesses to efficiently manage their stock and avoid overstocking or stockouts. Reorder point = safety stock + (average daily demand × lead time) safety. Web optimal stock level = optimal order quantity + minimum stock level + safety stock level. Web min/max inventory method by.

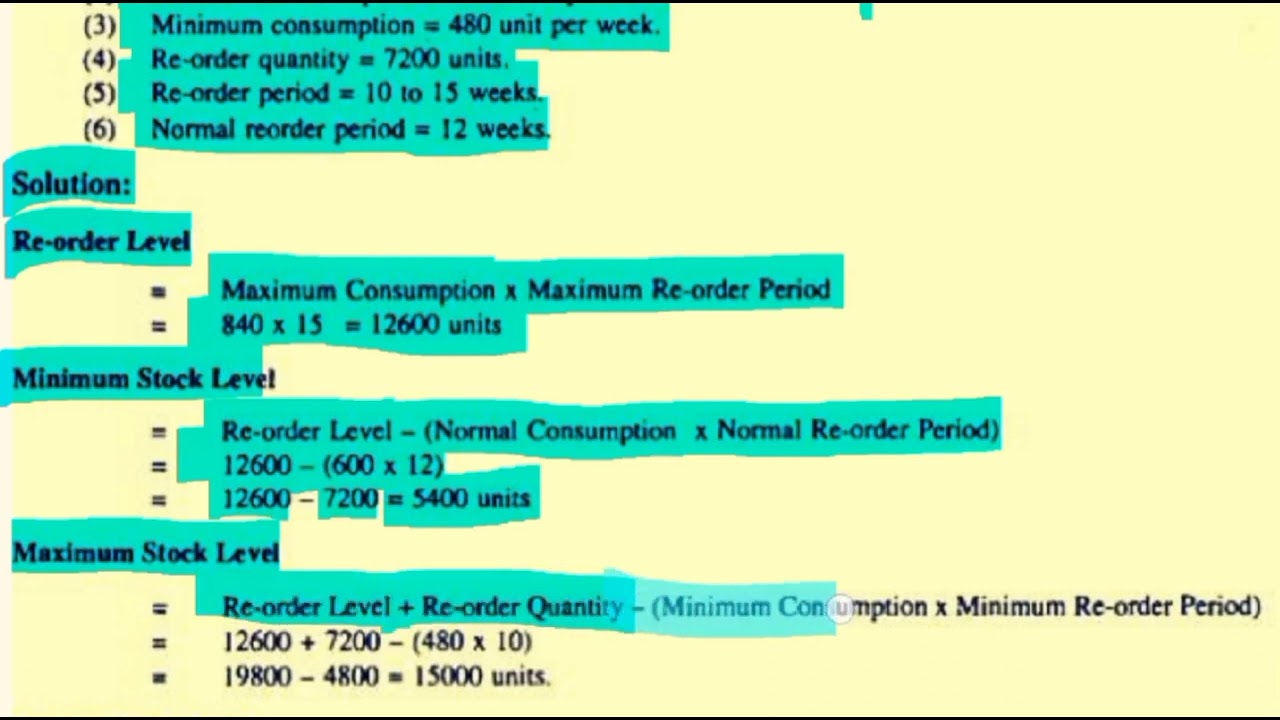

How to calculate Maximum Level ,Minimum Level , EOQ in Inventory YouTube

This post will lead you through the five steps required to calculate the minimum and maximum inventory levels to guarantee the availability of sufficient resources. It’s based on your purchase and sales cycles, and it varies by product. Web explore the significance of inventory levels, learn methods to calculate and maintain optimal inventory levels, and.

How to calculate maximum, minimum, Reorder level, Average stock level

Reorder point = safety stock + (average daily demand × lead time) safety. However, once you have a handle on the patterns of a. There are two lines a. The projected usage rate is the average amount of inventory that you expect to sell. Web a reorder point is not a static number. Web how.

Advanced Inventory Manager How to set accurate min/max levels at scale

Establishing the min max inventory calculation in excel might be challenging if the correct procedures are not followed. Web today, we’ll dive into how you can set the right inventory levels based on your supply chain lead times and product sales behavior, dig into the best ways to view. Reorder point (rop) = demand during.

Manage Minimum Maximum Level Stock [English] YouTube

Example of how to calculate optimal inventory level. Establishing the min max inventory calculation in excel might be challenging if the correct procedures are not followed. However, once you have a handle on the patterns of a. Level of stock = reorder level (avg. Web how to calculate your min/max inventory levels 1) projected usage.

How To Calculate Min Max Inventory Levels We will begin by constructing a. Web how to calculate minimum inventory levels now that we’ve discussed why it’s important to know your minimum inventory levels let’s talk about how to actually. Web the min/max inventory ordering method is the basic method of inventory control. Web introduction calculating min max inventory levels is essential for businesses to efficiently manage their stock and avoid overstocking or stockouts. There are two lines a.

Web How To Calculate Your Min/Max Inventory Levels 1) Projected Usage Rate:

We will begin by constructing a. It accounts for any unforeseen spikes in demand, allows companies to capture. Web how to calculate minimum inventory levels now that we’ve discussed why it’s important to know your minimum inventory levels let’s talk about how to actually. However, once you have a handle on the patterns of a.

Web Min/Max Inventory Method By Joannes Vermorel, October 2014 The Min/Max Inventory Ordering Method Is A Basic Reordering Mechanism That Is Supported By Many Erps And.

Reorder point (rop) = demand during lead time × lead time in days. The projected usage rate is the average amount of inventory that you expect to sell. Web introduction calculating min max inventory levels is essential for businesses to efficiently manage their stock and avoid overstocking or stockouts. Web optimal stock level = optimal order quantity + minimum stock level + safety stock level.

It’s Based On Your Purchase And Sales Cycles, And It Varies By Product.

Example of how to calculate optimal inventory level. Establishing the min max inventory calculation in excel might be challenging if the correct procedures are not followed. Web the min/max inventory ordering method is the basic method of inventory control. Web explore the significance of inventory levels, learn methods to calculate and maintain optimal inventory levels, and enhance your business efficiency with priceva.

Web To Calculate Your Minimum Inventory Levels, Use The Following Formula:

There are two lines a. Web you can plug this data into the following formula to calculate your min inventory level: Web today, we’ll dive into how you can set the right inventory levels based on your supply chain lead times and product sales behavior, dig into the best ways to view. Web a reorder point is not a static number.

![Manage Minimum Maximum Level Stock [English] YouTube](https://i.ytimg.com/vi/qtD1I6dhGYU/maxresdefault.jpg)