Injection Molding Tonnage Calculator

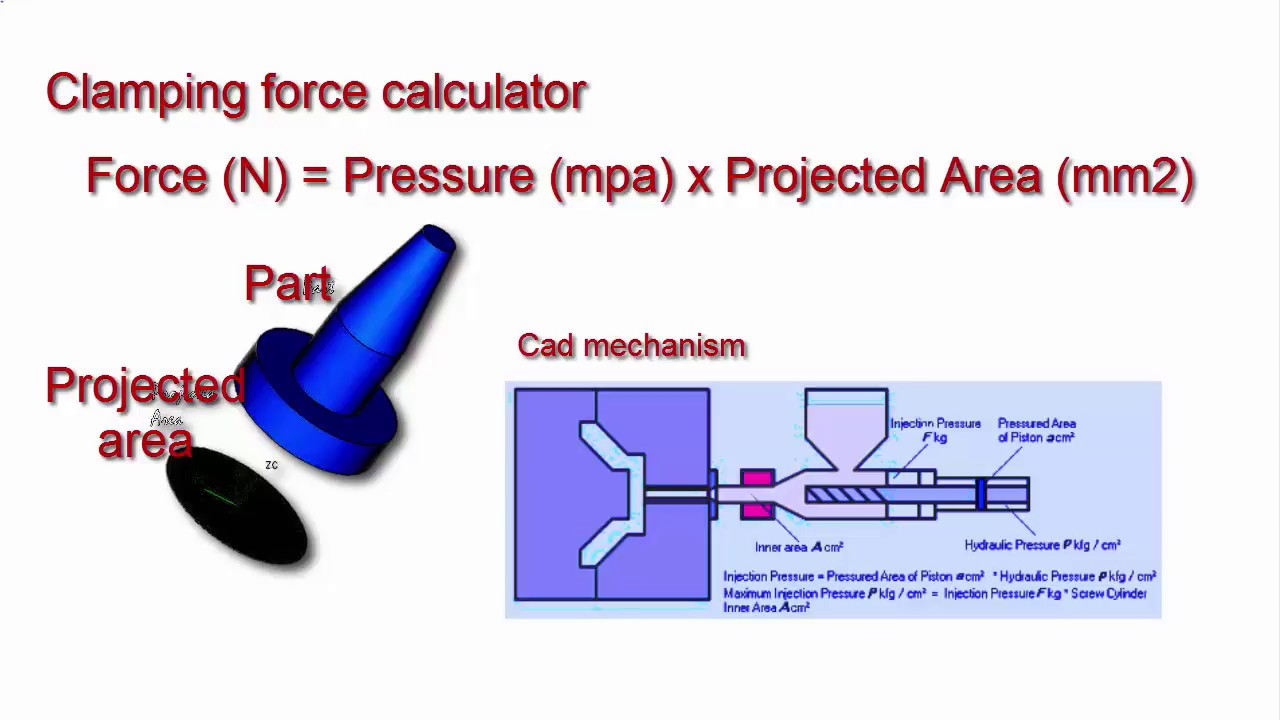

Injection Molding Tonnage Calculator - Web clamping tonnage calculation formula: Web designers in this video we learnhow to calculate injection mould clamping tonnage with easy and simpler way.#mouldtonnage #howtocalculateinjectionmouldingto. Web use the following calculator to get an estimate of the tonnage required to mould a rectangular or round part. If there are multiple cavities of the same size in the mold,. Calculate tonnage with all the information gathered, use the tonnage calculation formula:

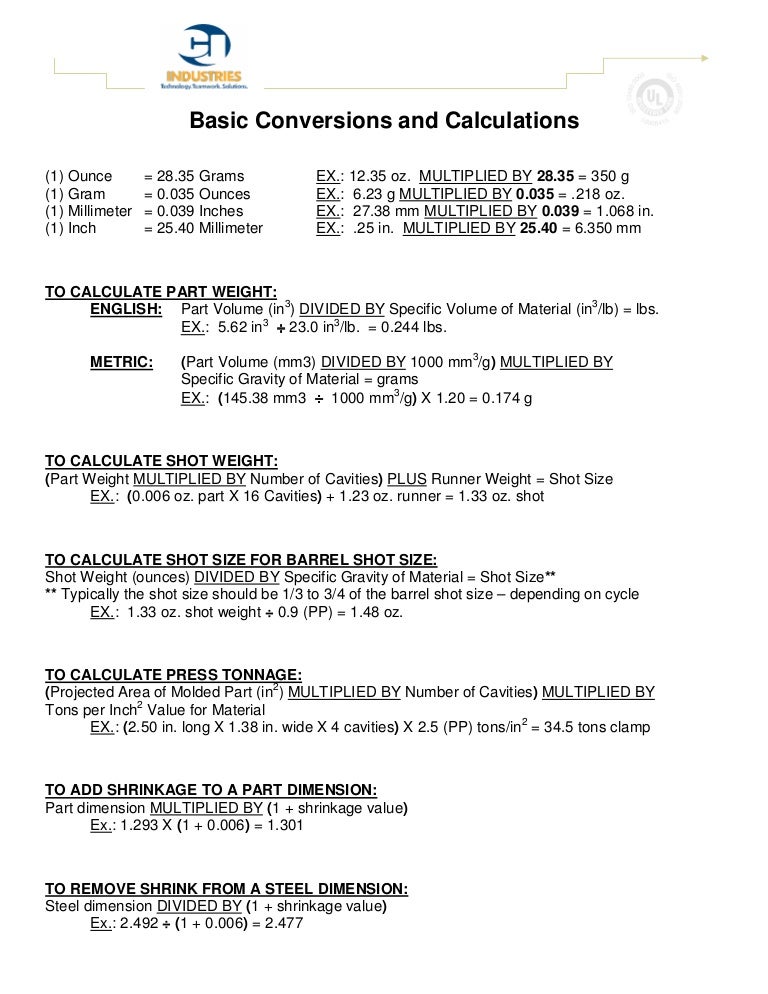

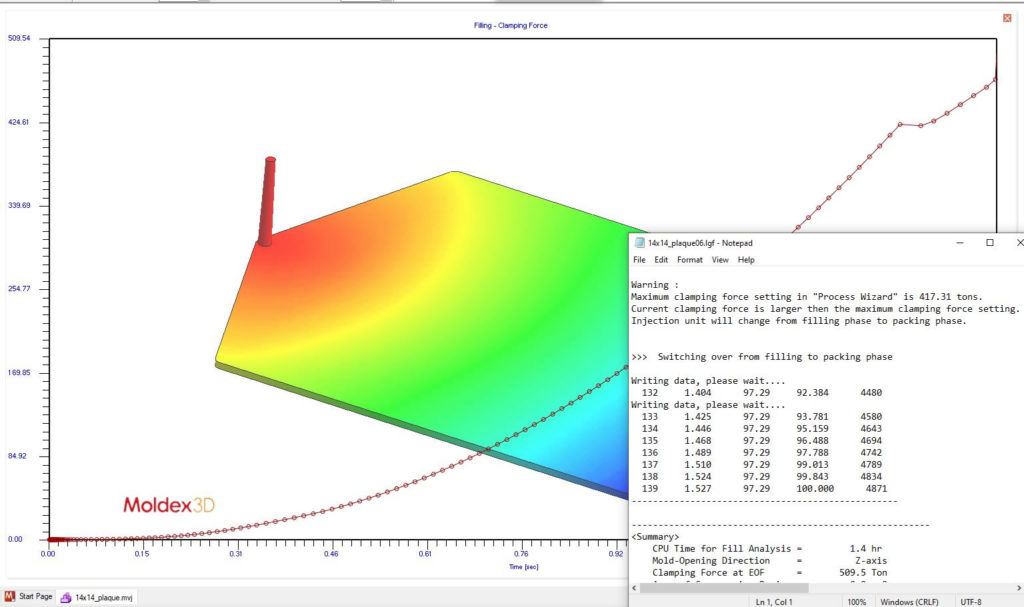

This process is critical to ascertaining the requisite tonnage, or clamping. Web it helps to estimate the clamping force required in the injection molding machine to keep the mold closed against the pressure of the plastic being injected. For a more exact calculation, and to ensure avoidance of over or under tonnage usage, mold. T = a x tf (tonnage factor). Web these charts can serve as a starting point for your calculations. To do this, toolmakers install a small channel in the parting line called a vent. Web now you can calculate necessary tonnage based on the projected area times the clamp factor for the material used.

Injection Moulding Machine Tonnage Calculation Formula Pdf

This is a essential skill for anyone working with injection moulding,. Web in addition, a press tonnage calculator can help you narrow your search for an injection molding partner. Web use the following calculator to get an estimate of the tonnage required to mould a rectangular or round part. Web these charts can serve as.

How to calculate tonnage in injection molding Projected area

Web the formula to calculate this is simple: Clamp tonnage equals projected area of the part, multiplied by the number of cavities, multiplied by the injection pressure. Web this injection molding press tonnage calculator is a tool for you to use and learn what size press would be required to manufacture your plastic part. A.

How to calculate Clamping tonnage of injection mould (PART 1) YouTube

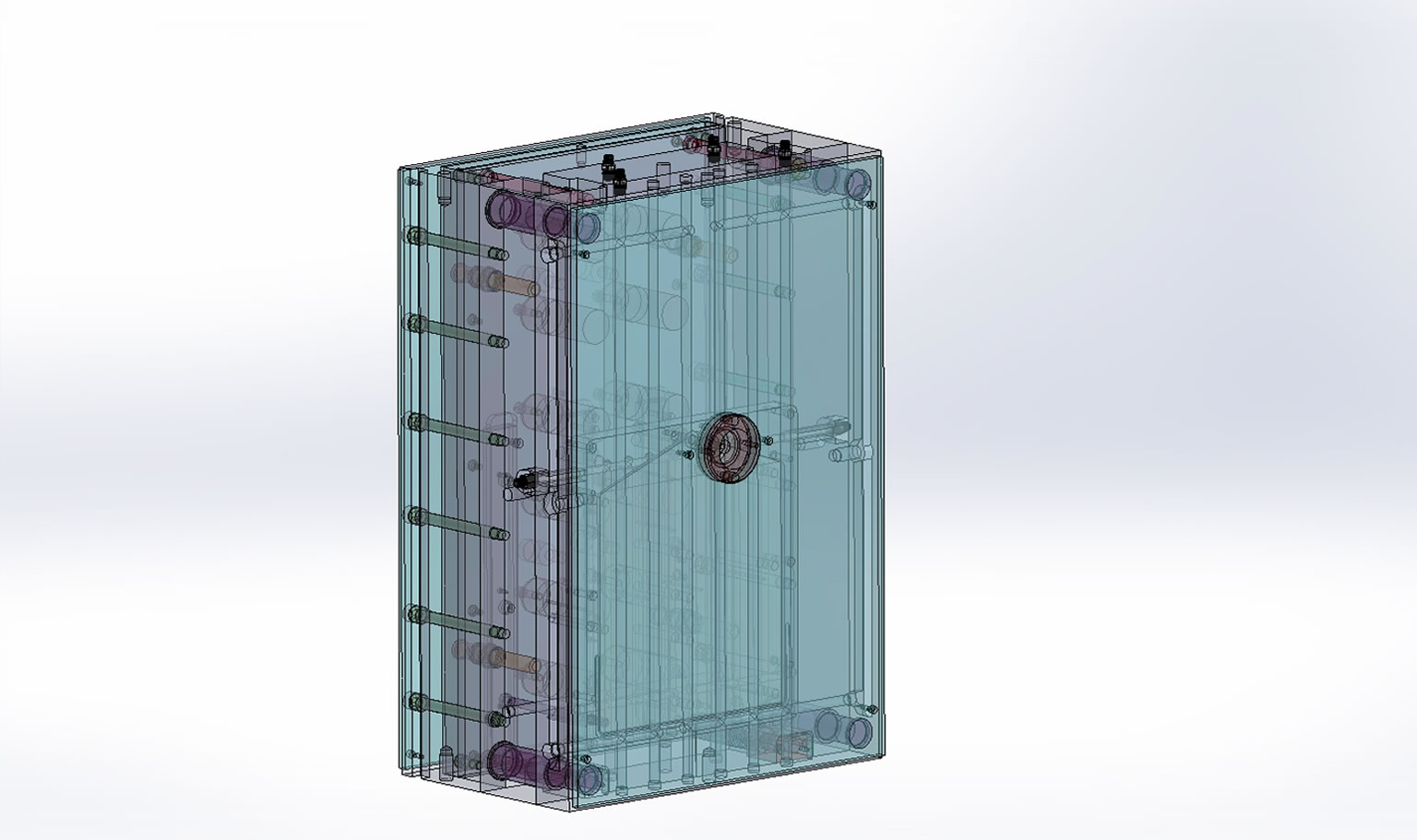

Web use the following calculator to get an estimate of the tonnage required to mould a rectangular or round part. Stainless steelprivate label3d printingfully integrated This is a essential skill for anyone working with injection moulding,. Web this injection molding press tonnage calculator is a tool for you to use and learn what size press.

Calculate Molding Clamp Tonnage for Plastic Injection

Calculate tonnage with all the information gathered, use the tonnage calculation formula: Corrugated tubes · condition monitoring · lead screws · track rollers · rod ends For a more exact calculation, and to ensure avoidance of over or under tonnage usage, mold. Web this is done by measuring the length and width of the mold’s.

HOW TO CALCULATE CLAMPING FORCE OR CALCULATE MACHINE TONNAGE IN PLASTIC

For a more exact calculation, and to ensure avoidance of over or under tonnage usage, mold. Web now you can calculate necessary tonnage based on the projected area times the clamp factor for the material used. Web how do you calculate tonnage for injection molding machine? T = a x tf (tonnage factor). Web in.

How to Calculate Injection Molding Machine Tonnage SS Machinery

Burn when you clamp up a tool, the cavities fill up with air that needs to be released. Web use the following calculator to get an estimate of the tonnage required to mould a rectangular or round part. For a more exact calculation, and to ensure avoidance of over or under tonnage usage, mold. If.

Tonnage Calculator HiTech Mold & Tool

This process is critical to ascertaining the requisite tonnage, or clamping. T = a x tf (tonnage factor). Calculate tonnage with all the information gathered, use the tonnage calculation formula: Web instead of using an injection molding machine tonnage calculator, many molders often estimate tonnage by using a “rule of thumb” equation that involves the.

8+ Injection Molding Tonnage Calculator NeveenDilyn

Burn when you clamp up a tool, the cavities fill up with air that needs to be released. Web now you can calculate necessary tonnage based on the projected area times the clamp factor for the material used. Web clamping tonnage calculation formula: Web this injection molding press tonnage calculator is a tool for you.

How to Calculate the Right Press Size for Injection Molding Plastic

This process is critical to ascertaining the requisite tonnage, or clamping. T = a x cf. Web now you can calculate necessary tonnage based on the projected area times the clamp factor for the material used. A = l x w or a= π r 2. Corrugated tubes · condition monitoring · lead screws ·.

Tonnage Calculator HiTech Mold & Tool

This process is critical to ascertaining the requisite tonnage, or clamping. Burn when you clamp up a tool, the cavities fill up with air that needs to be released. For a more exact calculation, and to ensure avoidance of over or under tonnage usage, mold. Web in this video, we're going to teach you how.

Injection Molding Tonnage Calculator Burn when you clamp up a tool, the cavities fill up with air that needs to be released. Web it helps to estimate the clamping force required in the injection molding machine to keep the mold closed against the pressure of the plastic being injected. Web to calculate the clamping force required for an injection molding machine, you can use the formula: This is a essential skill for anyone working with injection moulding,. Web molding clamp tonnage & pressure:

Web To Calculate The Clamping Force Required For An Injection Molding Machine, You Can Use The Formula:

This calculator is to be used as a guide and the results are. T = a x tf (tonnage factor). Clamping tonnage of injection molding machine once you have. A = l x w or a= π r 2.

Calculate Tonnage With All The Information Gathered, Use The Tonnage Calculation Formula:

Tonnage for an injection molding machine is calculated based on the projected area of the part. Web clamping tonnage calculation formula: Web in this video, we're going to teach you how to calculate clamping tonnage of injection moulding! Web the formula to calculate this is simple:

To Do This, Toolmakers Install A Small Channel In The Parting Line Called A Vent.

T = a x cf. Clamp tonnage equals projected area of the part, multiplied by the number of cavities, multiplied by the injection pressure. This process is critical to ascertaining the requisite tonnage, or clamping. Web instead of using an injection molding machine tonnage calculator, many molders often estimate tonnage by using a “rule of thumb” equation that involves the area of the part,.

Web Now You Can Calculate Necessary Tonnage Based On The Projected Area Times The Clamp Factor For The Material Used.

Web these charts can serve as a starting point for your calculations. Web how do you calculate tonnage for injection molding machine? Web designers in this video we learnhow to calculate injection mould clamping tonnage with easy and simpler way.#mouldtonnage #howtocalculateinjectionmouldingto. Press tonnage measurements are vital for plastic.