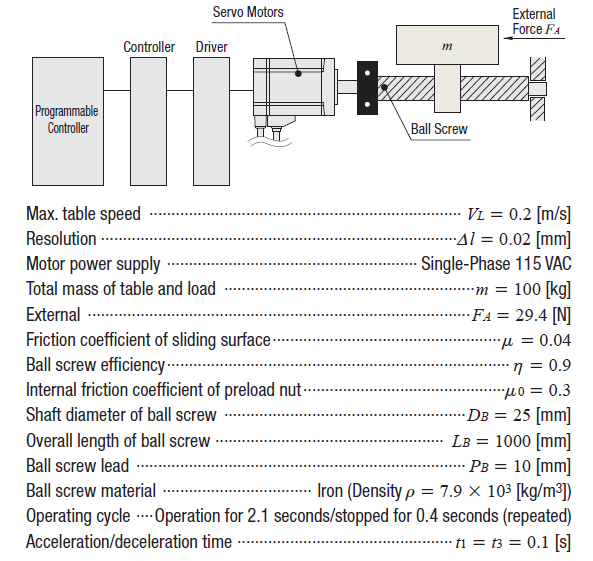

Motor Sizing Calculator

Motor Sizing Calculator - Web r = 2in, wg = 600rev/min * 1min/60sec = 10 rev/sec. Provides typical fla, sc protection, conductor size, and motor starter information. Web to calculate load torque, multiply the force (f) by the distance away from the rotational axis, which is the radius of the pulley (r). The calculator typically prompts you to. If the mass of the load (blue box) is.

Web these online motor sizing tools are designed to make sizing a motor faster and easier. While knowing these calculations is a good way to get a sense of the size of the motor needed and a. Provides typical fla, sc protection, conductor size, and motor starter information. T = time to start (seconds) n = velocity at load (rpm) t a = average torque during start (ft. Refer to page 3 for calculating the speed, load torque and load inertia for. Electric motor time to start calculator where: Web t = [ n x wr2 ] / [ ta x 308 ] open:

Three Phase Motor Full Load Amps Calculator

Web we will rotate the arm three times (360 degrees times 3 is equal to 1080 degrees). Then, fill in the rest of the form. Electrical units, amps and electrical wiring, wire gauge and awg, electrical formulas and motors. At the motor drive shaft of the mechanism. Provides typical fla, sc protection, conductor size, and.

Motor Full Load Currents Guide Sizing a Current Transformer

Monday to friday 8:30am est to. At the motor drive shaft of the mechanism. ° ° = for stepper motors input step angle we're here to help business hours: ° ° = for stepper motors input step angle we're here to help business hours: Electrical units, amps and electrical wiring, wire gauge and awg, electrical.

How to Determine the Motor Size for Your Project? YouTube

Web how to size a motor? Torque, angular velocities and power of the motor from weight, wheel diameter, linear velocity,. Enter the required parameters into the designated input fields, click the “calculate” button, and the. T = time to start (seconds) n = velocity at load (rpm) t a = average torque during start (ft..

Generators Sizing Calculations Part Twelve Electrical Knowhow

Web quickly calculate the necessary torque, speed, stopping accuracy and system inertia essential to selecting a proper motor for the application. While knowing these calculations is a good way to get a sense of the size of the motor needed and a. T = time to start (seconds) n = velocity at load (rpm) t.

Stepper Motor Sizing Calculator

Web the motor sizing calculator simplifies the complex process of selecting the right motor for your application. Monday to friday 8:30am est to. Draw/diagram the system to establish the relative location of the load mechanics. If the mass of the load (blue box) is. While knowing these calculations is a good way to get a.

3 Phase Motor Hp To Kw Calculator

Electrical units, amps and electrical wiring, wire gauge and awg, electrical formulas and motors. Electric motor time to start calculator where: Refer to page 3 for calculating the speed, load torque and load inertia for. Web we will rotate the arm three times (360 degrees times 3 is equal to 1080 degrees). Provides typical fla,.

Brushless Motor Size Chart

° ° = for stepper motors input step angle we're here to help business hours: Web quickly calculate the necessary torque, speed, stopping accuracy and system inertia essential to selecting a proper motor for the application. Electrical units, amps and electrical wiring, wire gauge and awg, electrical formulas and motors. Refer to page 3 for.

Hydraulic Power Unit Design Step by step Calculation Accumulator

Web we will rotate the arm three times (360 degrees times 3 is equal to 1080 degrees). The calculator typically prompts you to. These forms calculate the necessary torque, speed, stopping accuracy and system. Torque, angular velocities and power of the motor from weight, wheel diameter, linear velocity,. Web to calculate load torque, multiply the.

Motor Sizing Basics Part 3 How to Calculate Speed, Acceleration Torque

Provides typical fla, sc protection, conductor size, and motor starter information. Web calculate the value for load torque, load inertia, speed, etc. ° ° = for stepper motors input step angle we're here to help business hours: Electric motor time to start calculator where: Monday to friday 8:30am est to 5:00pm pst. These forms calculate.

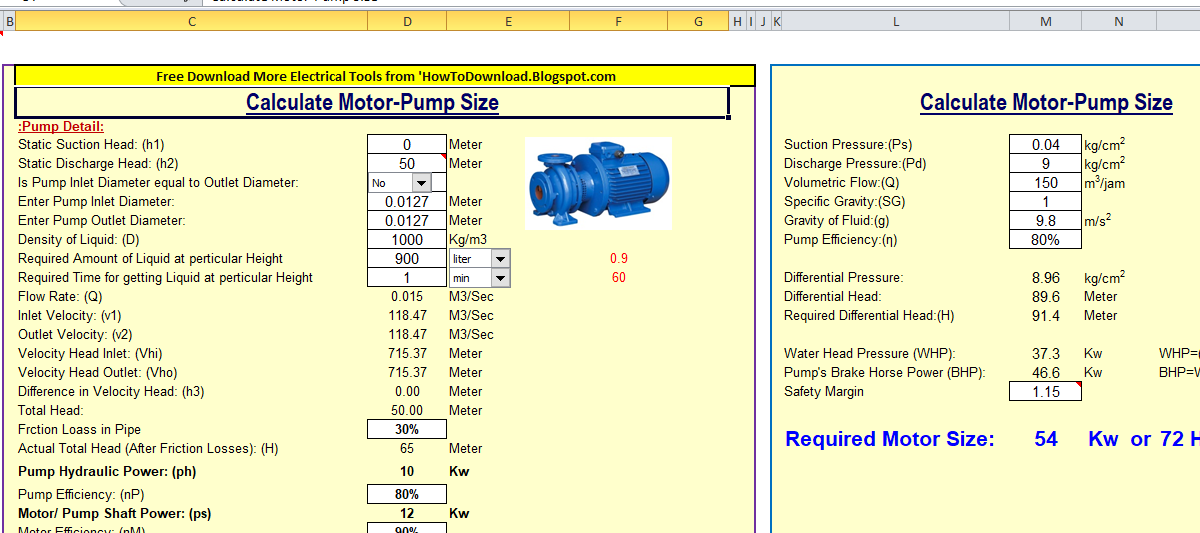

Calculate MotorPump Size (Calculator) Free Electrical Software and

The calculator typically prompts you to. Torque, angular velocities and power of the motor from weight, wheel diameter, linear velocity,. Web the motor sizing calculator simplifies the complex process of selecting the right motor for your application. While knowing these calculations is a good way to get a sense of the size of the motor.

Motor Sizing Calculator ° ° = for stepper motors input step angle we're here to help business hours: Provides typical fla, sc protection, conductor size, and motor starter information. Torque, angular velocities and power of the motor from weight, wheel diameter, linear velocity,. Electric motor time to start calculator where: Web we will rotate the arm three times (360 degrees times 3 is equal to 1080 degrees).

While Knowing These Calculations Is A Good Way To Get A Sense Of The Size Of The Motor Needed And A.

These forms calculate the necessary torque, speed, stopping accuracy and system. Web we will rotate the arm three times (360 degrees times 3 is equal to 1080 degrees). Web to calculate load torque, multiply the force (f) by the distance away from the rotational axis, which is the radius of the pulley (r). Develop the torque and inertia equations that model the system mechanics.

Monday To Friday 8:30Am Est To 5:00Pm Pst.

Web r = 2in, wg = 600rev/min * 1min/60sec = 10 rev/sec. Web quickly calculate the necessary torque, speed, stopping accuracy and system inertia essential to selecting a proper motor for the application. Web the motor sizing calculator simplifies the complex process of selecting the right motor for your application. Then, fill in the rest of the form.

Electric Motor Time To Start Calculator Where:

Draw/diagram the system to establish the relative location of the load mechanics. The calculator typically prompts you to. If the mass of the load (blue box) is. Web using the stepper motor sizing calculator is straightforward.

Web T = [ N X Wr2 ] / [ Ta X 308 ] Open:

Torque, angular velocities and power of the motor from weight, wheel diameter, linear velocity,. ° ° = for stepper motors input step angle we're here to help business hours: Monday to friday 8:30am est to. Web how to size a motor?